EPC Services

SEAWING goes beyond the ordinary EPC structure. We design, manufacture, transport, construct, test and commission the entire mooring infrastructure – and remain on-site to support the first tanker loading operation, ensuring the smooth system start-up and transfer of operation readiness. This approach reduces risk and guarantees a performance proven handover.

EPC processes of SEAWING include but are not limited to the followings:

- Engineering management

- Time planning with CPM

- Document control management

- Resource planning

- Risk management

- Procurement and supplier management

- Quality assurance and quality control

- Logistics management

- Supply complete equipment

- Installation, test and commissioning

2.1. CALM Buoy Terminals

Over the years, SEAWING has successfully designed and delivered cost effective Turret Buoys to marine terminal operators and refineries worldwide, to allow offshore loading of tankers of any size. Our Buoys enable flexibility in operation and low operation and maintenance needs thanks to the high quality and proven technology.

Project Management approach of SEAWING offers a field proven CALM Buoy design, enabling shortest delivery times at lowest costs. Standardized options are also available as well as customization to Client specific requirements. As a part of total quality assurance and quality control management procedure of SEAWING, experienced design, sales, project management and on-field teams are available to provide on-time support to all of Customers.

All Buoys are moored to the seabed by using a Catenary Anchor Leg Mooring (CALM) system. Connected hoses and pipelines transfer the product between the shuttle tanker and the storage terminal.

Multiple products can be transferred simultaneously and typically include hydrocarbons, such as fluid or condensate, liquefied petroleum (LPG), potable water and refined products like methanol, ethanol and ammonia. Wired, telemetry and optical signals, electrical power and hydraulics are included.

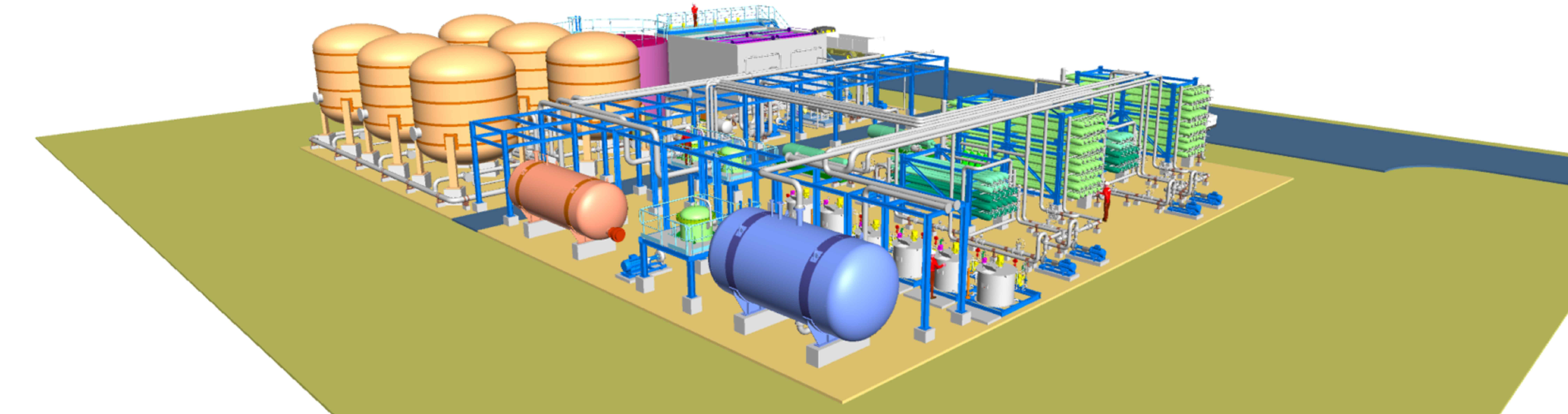

2.2. Desalination Plants

SEAWING approach to the design, procurement, and construction of Desalination Projects, ensures that they are completed on time, within budget, and to the required quality standards. Key stages of Desalination Plants comprise the following:

- Pre-treatment: Involves removing suspended solids, adjusting pH, and adding inhibitors to control scaling. It includes elements like seawater intake structures, pump houses, and water treatment plants.

- Desalination: Uses thermal methods (e.g., distillation) or membrane processes (e.g., reverse osmosis) to separate salt from water.

- Post-treatment: Involves pH adjustment, degasification, and addition of chemicals for water stabilization before distribution.

2.3. Power Generation

SEAWING offers a range of Power Plants tailored to different applications and sizes. The Power Plants we designed and provided are well regarded for:

- High reliability

- Exceptional operability

- Ease of maintenance

Our gas turbine portfolio delivers competitive, efficient, and flexible solutions from 30 to 140 MW, featuring different configurations. These models can operate on liquid fuels (diesel), natural gas, or other jet fuels. Our portfolio also includes Aero-derivative turbines which provide exceptional grid response, ensuring reliable, cost-effective, and secure power for NOC (National Oil Corporation).

SEAWING also contributes to the improvement of the Power Plants and maximizes asset value of the Client by providing emergency service, preventive maintenance, training, and support for operation and maintenance (O&M) with state-of-the-art technology.